A/C Compressor Clutch Replacement Procedure

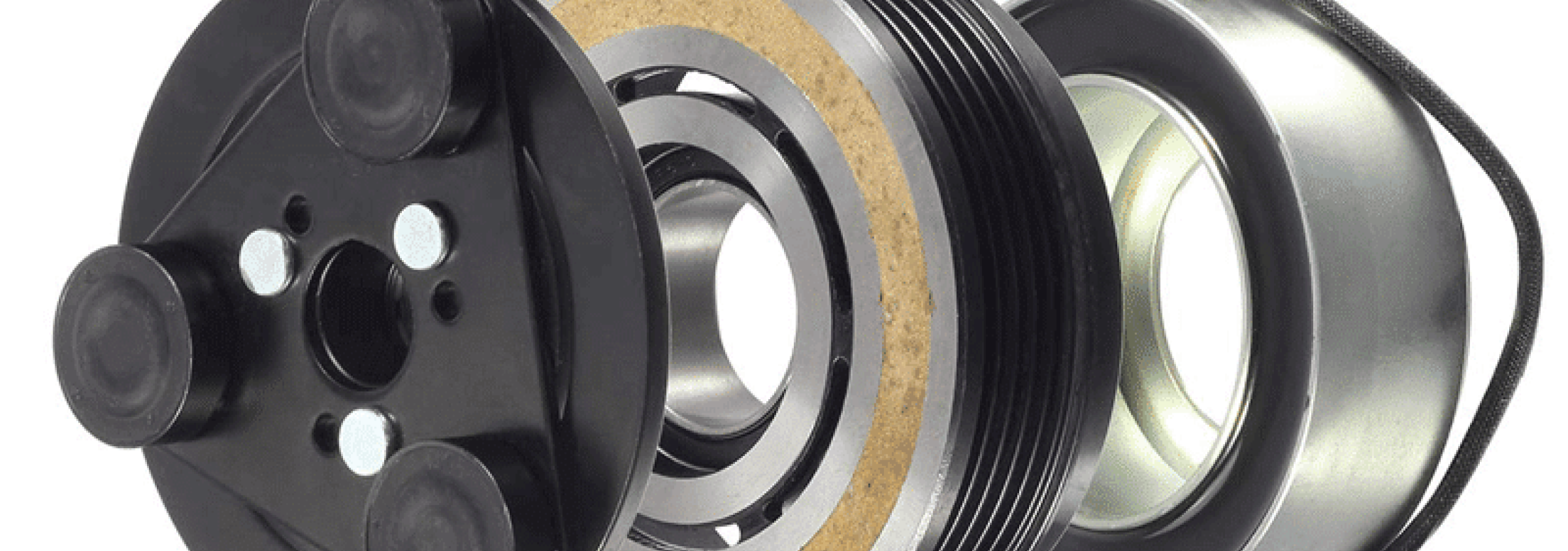

- A typical A/C compressor is shown in illustrations.

1. Disconnect and isolate the negative battery cable.

2. Remove the accessory drive belt.

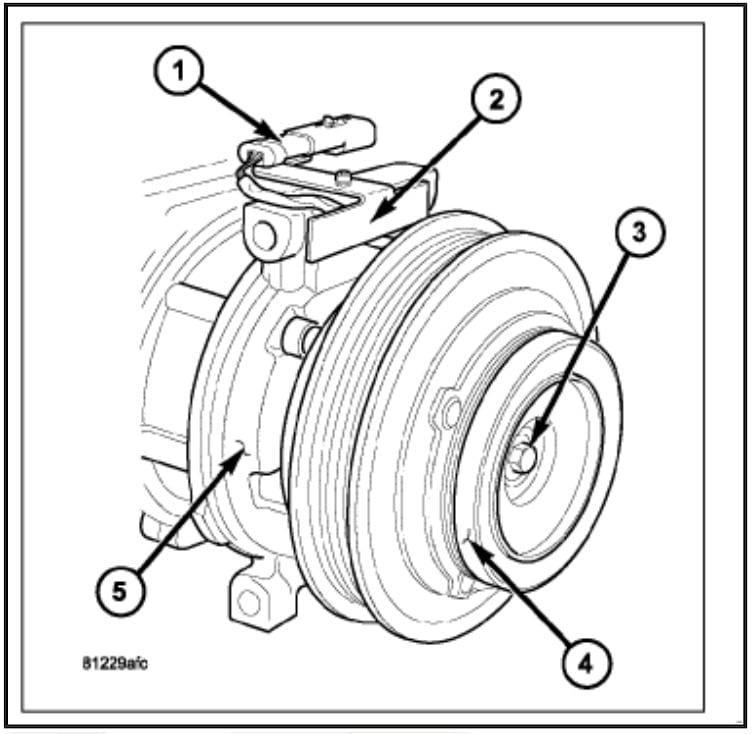

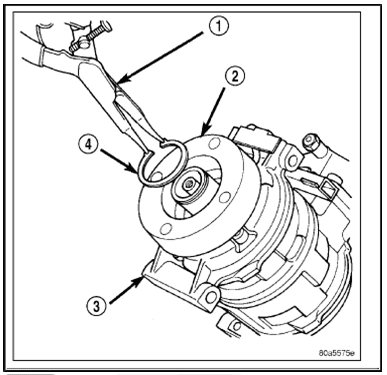

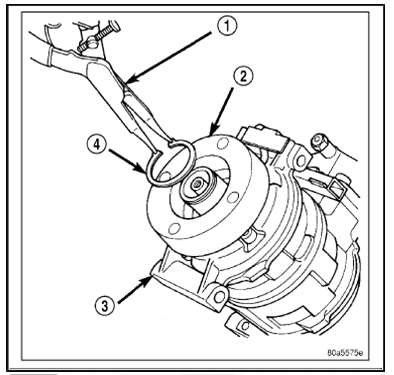

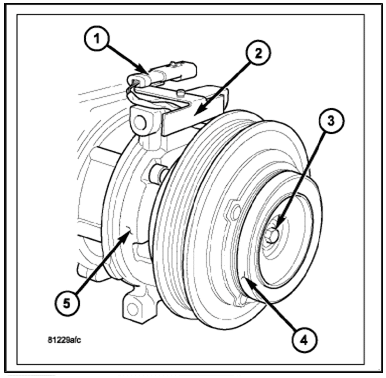

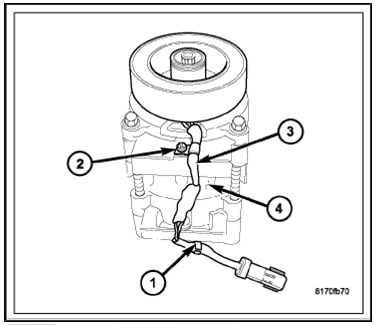

3. Disconnect the engine wire harness from the A/C compressor clutch field coil connector (1) located on the top of the A/C compressor (5).

4. Remove the bolts that secure the A/C compressor to the engine and support the A/C compressor.

5. Carefully remove the compressor clutch field coil connector and wire lead from the connector bracket (2).

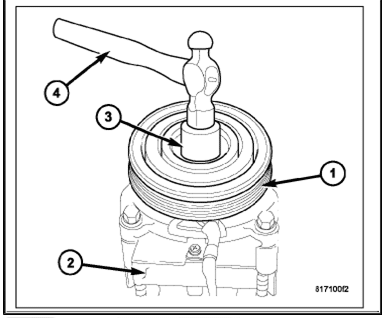

6. Remove the compressor shaft bolt (3). A band-type oil filter wrench or a strap wrench may be used to hold the clutch plate (4) from rotating during bolt removal.

CAUTION: Do not pry between the clutch plate and the pulley and bearing assembly to remove the clutch plate from the compressor shaft as this may damage the clutch plate.

NOTE: Use care not to lose any clutch shim(s) during the removal of the clutch plate, as they may be reused during the clutch plate installation process.

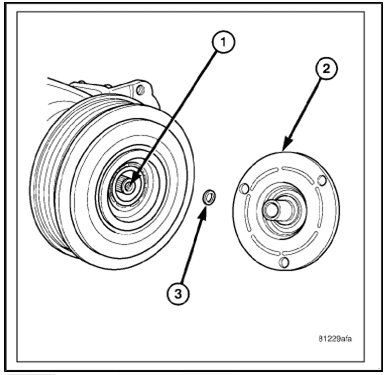

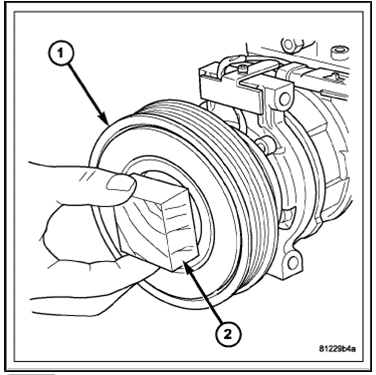

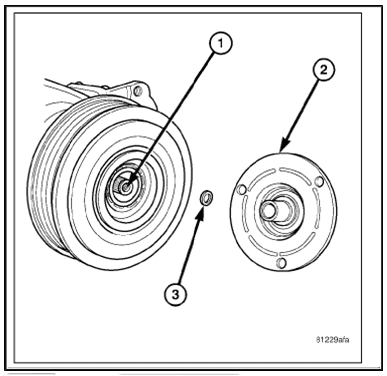

7. Tap the clutch plate (2) lightly with a plastic mallet to release it from the splines on the compressor shaft (1) and remove the clutch plate and shim(s) (3).

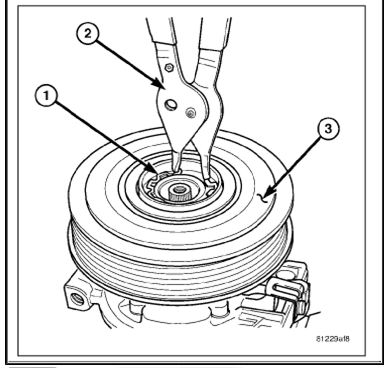

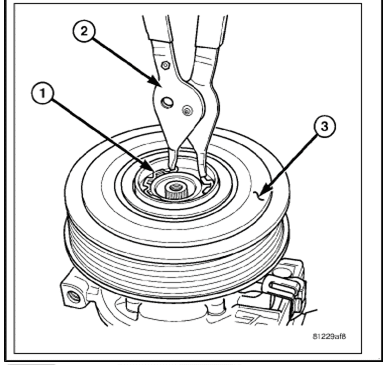

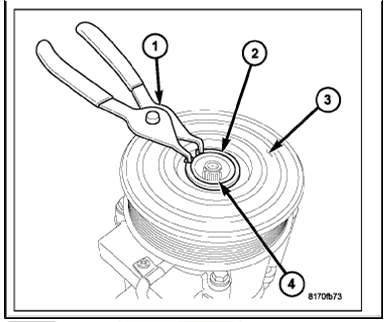

8. Using snap ring pliers (2), remove the snap ring (1) that secures the pulley and bearing assembly (3) to the front of the A/C compressor and remove the pulley and bearing assembly.

9. Using snap ring pliers (1), remove the snap ring (4) that secures the compressor clutch field coil (2) to the front of the A/C compressor (3) and remove the field coil.

INSTALLATION

NOTE: Typical A/C compressor is shown in illustrations.

1. Align the dowel pin on the back of the compressor clutch field coil (2) with the hole in the front of the A/C compressor (3) and position the field coil onto the compressor. Be certain that the compressor clutch field coil wire lead is properly routed so that it is not pinched between the A/C compressor and the field coil.

CAUTION: The snap ring must be installed and seated into the groove or it will vibrate out, resulting in a clutch failure and severe damage to the A/C compressor. Lock the snap ring back into its seating position, securing the compressor clutch field coil to the A/C compressor. The bevel side of the snap ring must face outward and both snap ring eyelets must be oriented to the right or to the left of the field coil dowel pin location on the A/C compressor.

2. Using snap ring pliers install the snap ring (4) that secures the compressor clutch

field coil to the front of the A/C compressor. Check that the snap ring is seated within the groove and oriented correctly.

- Be certain to position the compressor clutch field coil wire lead so that it is not damaged during A/C compressor pulley and bearing installation.

- When installing the pulley and bearing assembly, DO NOT mar the friction surfaces of the pulley or premature failure of the clutch will result.

3. Install the pulley and bearing assembly (1) onto the front of the A/C compressor. If necessary, tap the pulley gently with a block of wood (2) placed on the pulley friction surface.

CAUTION: The snap ring must be fully and properly seated in the groove or it will vibrate out, resulting in a clutch failure and severe damage to the A/C compressor. The bevel side of the snap ring must face outward.

4. Using snap ring pliers (2), install the snap ring (1) that secures the pulley and bearing assembly (3) to the front of the A/C compressor. Be certain that the snap ring is fully and properly seated in the groove.

5. If the original clutch plate (2) and pulley and bearing assembly are to be reused, reinstall the original shim(s) onto the compressor shaft (1). If a new clutch plate and pulley and bearing assembly are being used, install a trial stack of shims 2.54 mm (0.010 in.) thick onto the compressor shaft.

6. Install the clutch plate (4) onto the front of the A/C compressor (5).

7. Install the compressor shaft bolt (3). Tighten the bolt to 19 N.m (168 in.lbs.)

- The shims may compress after tightening the shaft bolt. Check the air gap in four or more places to verify the air gap is correct. Spin the pulley before performing a final check of the air gap.

- On models with the clutch plate recessed into the pulley, use a 90-degree wire gap gauge to measure the clutch air gap. On other models, use a blade-type feeler gauge to measure the air gap.

8. With the clutch plate assembled tight against the shim(s), measure the air gap between the clutch plate and the pulley and bearing assembly. The air gap should be between 0.35 – 0.60 mm (0.014 – 0.024 in.). If the air gap is not between specifications, add or subtract shims as needed until the correct air gap is obtained.

CAUTION: Be certain that the compressor clutch field coil wire harness is properly routed so that it is not pinched between the A/C compressor and the field coil connector bracket.

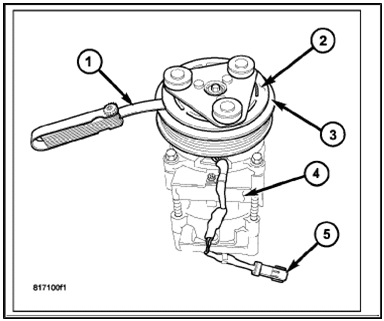

9. Carefully route the compressor clutch field coil wire lead behind the connector bracket (2).

10. Install the compressor clutch field coil connector (1) onto the connector bracket.

11. Position the A/C compressor to the engine and install the retaining bolts.

12. Connect the engine wire harness to the compressor clutch field coil connector.

13. Install the accessory drive belt.

14. Reconnect the negative battery cable.

VISTEON STYLE COMPRESSOR

REMOVAL

NOTE: If the A/C compressor clutch can be serviced in the vehicle, the refrigerant system can remain fully charged during compressor clutch, pulley and bearing assembly or field coil replacement.

1. Disconnect and isolate the negative battery cable.

2. Remove the accessory drive belt.

3. Raise and support the vehicle.

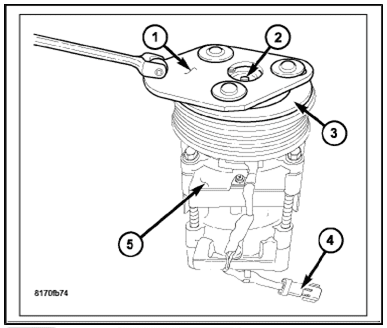

4. Disconnect the engine wire harness from the clutch field coil connector (4).

5. Remove the bolts that secure the A/C compressor (5) to the mounting bracket.

6. Remove the A/C compressor from the mounting bracket and support the compressor while servicing the clutch.

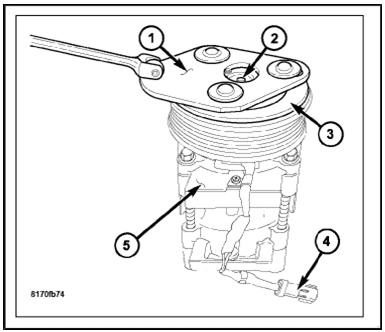

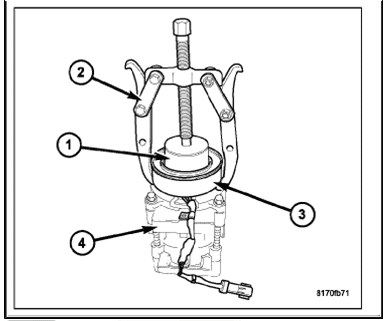

7. Using compressor clutch holding fixture (1), remove the bolt (2) that secures the clutch plate (3) to the compressor shaft.

- The clutch plate can be removed from the compressor shaft by hand or, if required, pressed off with an 8 x 1.25 mm bolt.

- Clutch plate shim(s) may remain inside the hub of the clutch plate. Be sure to remove all of the shims from inside the hub or from the end of the compressor shaft.

8. Remove the clutch plate and shim(s) from the A/C compressor. If required, install an 8 x 1.25 mm bolt into the centre of the clutch plate and turn the bolt clockwise until the clutch plate is completely removed from the A/C compressor.

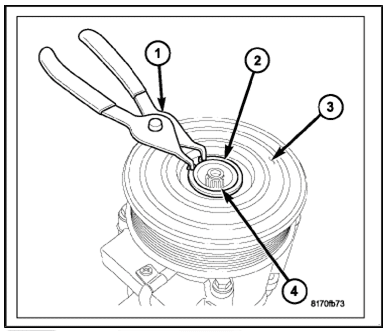

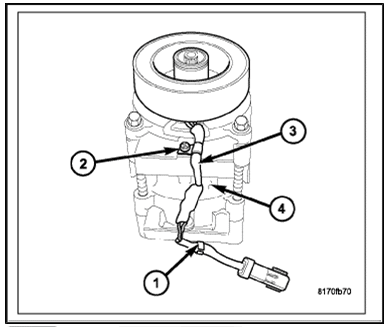

9. Using snap ring pliers (1), remove the snap ring (2) that secures the pulley and bearing assembly (3) to the front of the A/C compressor (4).

NOTE: The pulley and bearing assembly can be removed from the compressor by hand or, if required, with a two-jaw puller.

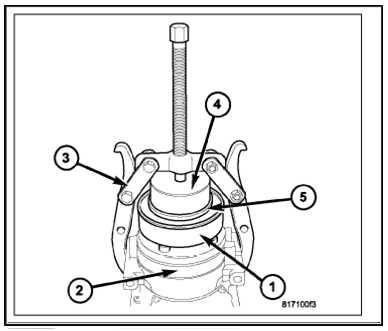

10. Remove the pulley and bearing assembly (1) from the front of the A/C compressor (2). If required, install a two jaw puller (3) and turn the puller centre-bolt clockwise until the pulley and bearing assembly are completely removed.

11. Remove the plastic retaining clip (1) and the screw (2) that secures the clutch field coil wire lead and connector (3) to the A/C compressor (4).

12. Using compressor field coil remover tool (1) and a two jaw puller (2), remove the clutch field coil (3) from the front of the A/C compressor (4).

INSTALLATION

1. Position the A/C clutch field coil (1) squarely onto the front of the A/C compressor (2).

CAUTION: Position the A/C clutch field coil so that the coil positioning tabs and the wire harness lead are oriented in the correct direction. Failure to correctly position the field coil on the A/C compressor will result in field coil damage.

2. Align the field coil positioning tabs to the recessed area at the front of the A/C compressor and install the clutch field coil onto the compressor using a two jaw puller (3), compressor field coil installer tool (4) and the compressor field coil installer spacer (5)

3. Position the clutch field coil wire lead and connector (3) to the A/C compressor (4) and install the plastic retaining clip (1) and the screw (2) that secures the wire lead to the compressor. Tighten the screw to 4 N.m (35 in. lbs.).

4. Align the pulley and bearing assembly (1) squarely onto the front of the A/C compressor (2).

NOTE: A distinct change of sound during the clutch pulley tapping process indicates that the pulley and bearing assembly has bottomed out against the compressor housing.

5. Using a clutch pulley installation tool (3) and a small plastic or rubber hammer (4), install the pulley and bearing assembly onto the front of the A/C compressor. Tap the installer with a hammer until the pulley and bearing assembly has bottomed against the compressor housing.

CAUTION: If the snap ring is not fully seated in the groove it will vibrate out, resulting in clutch failure and severe damage to the A/C compressor.

NOTE: Install the snap ring with the beveled side of the snap ring facing outward.

6. Using snap ring pliers (1), install the snap ring (2) that secures the pulley and bearing assembly (3) to the front of the A/C compressor (4). Make sure the snap ring is properly seated in the groove.

7. Verify that there is adequate clearance for the clutch field coil wire lead and connector (4) between the compressor housing and the pulley.

NOTE: When installing an original or a new clutch assembly, try the original shims first. When installing a clutch onto a compressor that previously did not have a clutch, use the 1.0, 0.50 and 0.13 millimeter (0.040, 0.020 and 0.005 inch) shims from the clutch hardware package which is provided with the new clutch.

8. Install the clutch shims onto the compressor shaft.

9. Using a A/C compressor clutch holding fixture tool (1), install the bolt (2) that secures the clutch plate (3) to the A/C compressor (5). Hold the clutch plate stationary with the holding fixture and tighten the bolt to 15 N.m (133 in. lbs.)

10. Using a feeler gauge (1), check the air gap between the clutch plate (2) and the pulley and bearing assembly (3). If the air gap is not 0.35 to 0.75 millimeter (0.014 to 0.030 inch), add or subtract shims as required.

11. Position the A/C compressor (4) onto the mounting bracket.

12. Install the bolts that secure the A/C compressor to the mounting bracket. Tighten the bolts to 23 N.m (17 ft. lbs.).

13. Connect the engine wire harness to the compressor clutch field coil connector (5).

14. Lower the vehicle.

15. Install the accessory drive belt.

16. Reconnect the negative battery cable.

17. Perform the Clutch Break-in Procedure.