Your vehicle’s air conditioning system plays an integral role in maintaining comfort on the road. Two of its important components, the TX (Thermal Expansion) valve and the AC compressor, are critical for regulating the cooling process and ensuring that your car’s cabin stays at a comfortable temperature. Understanding how these components function, the common issues that can arise, and the maintenance steps required will help you keep your AC system in top condition and avoid costly repairs.

What is a TX Valve, and Why is it Important?

The TX valve, or thermal expansion valve, is responsible for controlling the amount of refrigerant entering the evaporator. By adjusting the flow based on the air temperature inside the cabin, the TX valve maintains a balanced cooling effect. When functioning correctly, the TX valve ensures efficient temperature regulation, reduced strain on the AC system, and extended compressor life.

Key Functions of the TX Valve

- Regulates Refrigerant Flow: The TX valve ensures the right amount of refrigerant is delivered to the evaporator.

- Maintains Consistent Temperature: By controlling the flow, the TX valve helps maintain a stable cabin temperature.

- Improves Efficiency: A properly working TX valve helps the entire AC system function more efficiently.

The Role of the AC Compressor in Vehicle Cooling

The AC compressor is often referred to as the “heart” of the AC system. It pressurises and circulates refrigerant, allowing heat to be released and cool air to flow through the cabin. Without a properly functioning compressor, the AC system cannot produce cold air, making it essential to identify and address compressor issues early.

Key Functions of the AC Compressor in Car Conditioning

- Circulates Refrigerant: The compressor pumps refrigerant through the system to produce cooling.

- Pressurises Refrigerant: Compressing refrigerant gas enables the cooling process.

- Ensures Cooling Consistency: A healthy compressor maintains a steady cooling effect inside the vehicle.

Common Signs of TX Valve and Compressor Failure

Both the TX valve and the AC compressor can experience wear over time, leading to diminished performance or even system failure. Recognising the signs early can help you avoid complete AC breakdowns and maintain comfort.

Symptoms of TX Valve Issues

- Inconsistent Cooling: If the TX valve malfunctions, you may notice inconsistent cabin temperatures.

- Frost on the AC Evaporator: A faulty TX valve may cause refrigerant to freese on the evaporator, affecting cooling performance.

- Unusual Noises: Hissing sounds may indicate that the TX valve isn’t properly regulating refrigerant flow.

Symptoms of Compressor Failure

- Warm Air: If the AC only blows warm air, it’s likely a compressor issue.

- Loud Noises: Grinding or squealing noises can signify a failing compressor.

- Oil Leaks: Leaks around the compressor may indicate internal damage.

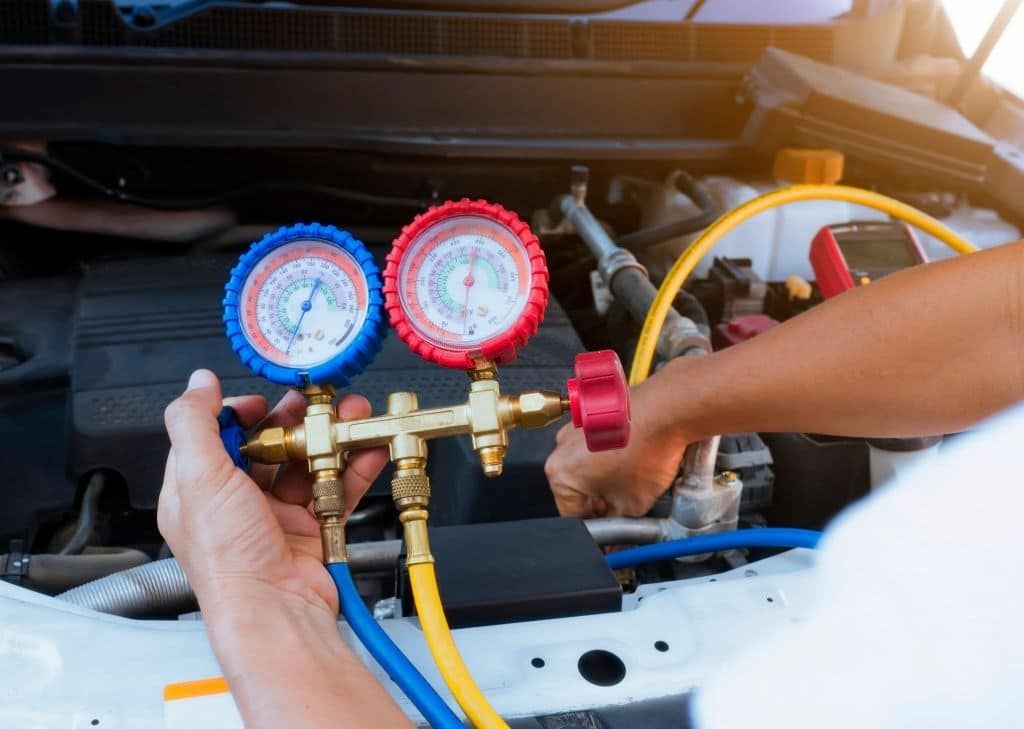

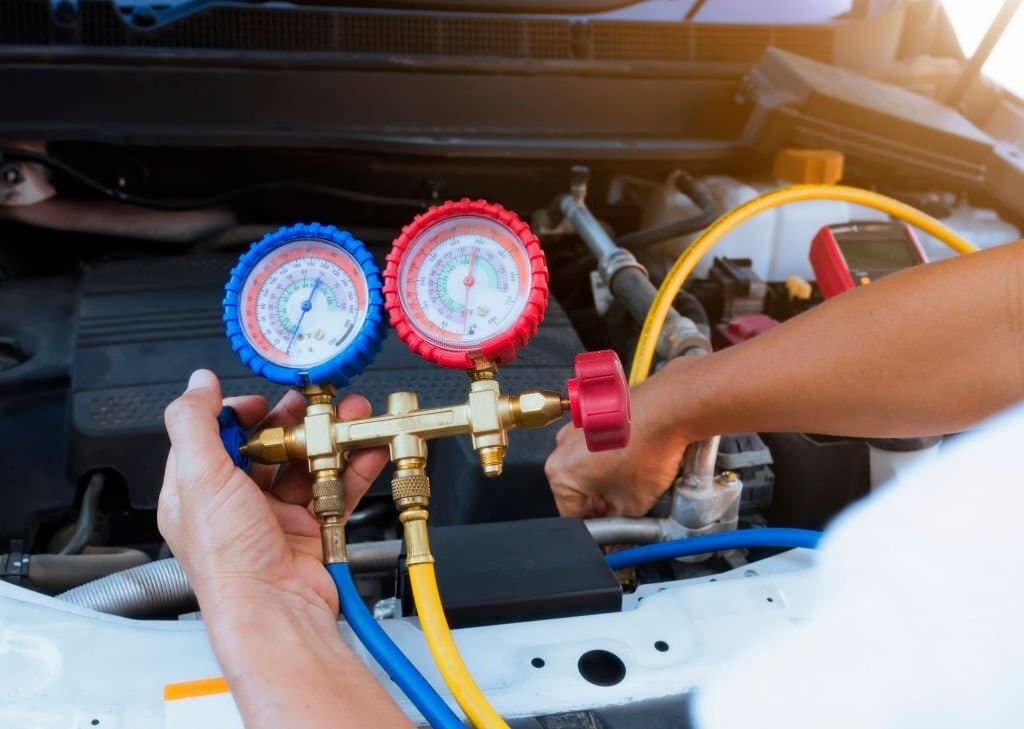

How to Maintain Your Vehicle’s TX Valve and AC Compressor in car

Routine maintenance can extend the life of your vehicle’s TX valve and compressor, ensuring efficient cooling and preventing costly repairs.

Steps to Maintain the TX Valve

- Check Refrigerant Levels: Low refrigerant can lead to TX valve issues.

- Inspect for Frost Buildup: Frost around the valve indicates an imbalance that needs attention.

- Monitor Cooling Efficiency: If you notice changes in cooling performance, have the TX valve inspected.

Steps to Maintain the AC Compressor

- Run the AC Regularly: Running the AC periodically, even in winter, keeps the compressor lubricated.

- Check for Refrigerant Leaks: Low refrigerant stresses the compressor, so fix any leaks promptly.

- Schedule Regular Inspections: Have a professional inspect the AC system annually to catch any early signs of compressor wear.

Replacing the TX Valve and AC Compressor: When is it Necessary?

While regular maintenance can prolong the lifespan of the TX valve and compressor, these components may need replacement over time. Knowing when to replace them can save you from unexpected breakdowns and discomfort.

- TX Valve Replacement: If you experience consistent cooling issues, frost buildup, or hissing sounds, it may be time to replace the TX valve. A professional inspection can confirm if replacement is necessary.

- AC Compressor Replacement: When the compressor fails to blow cold air or emits unusual sounds, a replacement may be the best solution. Professional repair can be costly, but a new compressor can improve cooling efficiency significantly.

FAQs about the TX Valve and AC Compressor in Cars

1. How can I tell if my TX valve needs replacement?

If your AC is blowing warm air or you find frost on the evaporator, the TX valve may need replacing. A professional inspection will confirm this.

2. Can I drive with a failing AC compressor?

While technically possible, driving with a failing compressor can affect other AC components and may lead to costly repairs.

3. Is TX valve repair expensive?

Repair costs vary, but addressing issues early on can save money by avoiding full system breakdowns.

Expert Advice: Choosing Quality Parts for TX Valve and Compressor Replacement

When replacing the TX valve or compressor, quality parts ensure optimal performance and durability. Invest in trusted brands or OEM parts to get the best results. Consult a qualified technician for recommendations tailored to your vehicle’s make and model.

Ensure Maintaining a Healthy TX Valve and AC Compressor for Comfortable Drives

The TX valve and AC compressor are fundamental to your vehicle’s cooling system. By understanding their roles, recognising signs of failure, and following maintenance tips, you can ensure a comfortable, efficient ride in all seasons. Routine care and prompt attention to any issues will keep your AC running smoothly and prevent the need for costly repairs.